Ministry of Plantation and Commodities (Kementerian Perladangan dan Komoditi)

The Ministry of Primary Industries (MPI) was established in 1972 to drive the development of Malaysia’s commodity industry and support economic growth. Initially, MPI focused on tin ore and rubber before expanding to include oil palm, cocoa, forestry, minerals, pineapple, and tobacco. In 2004, MPI was restructured as the Ministry of Plantation Industries and Commodities (KPPK). This restructuring transferred the Black Pepper Marketing Board (JPLH) from the Ministry of Agriculture to KPPK, while forestry, minerals, and geoscience responsibilities moved to the Ministry of Natural Resources and Environment. The Ministry underwent several name changes: it became the Ministry of Primary Industries (MPI) in 2018, reverted to MPIC in 2020, and was renamed the Ministry of Plantation and Commodities in 2022. The Ministry oversees the development of agricommodity plantations and industries, from production to marketing. The sector has progressed from exporting raw materials to producing higher value-added products, meeting global demand.

The Agri-commodity subsector—including oil palm, rubber, timber, cocoa, pepper, and kenaf—plays a crucial role in Malaysia’s economy by generating export revenue, creating jobs, and supporting smallholders.

Six agencies support the Ministry’s objectives:

Malaysian Palm Oil Board (MPOB)

Malaysian Rubber Board (MRB)

Malaysian Timber Industry Board (MTIB)

Malaysia Cocoa Board (LKM)

Malaysia Pepper Board (MPB)

National Kenaf and Tobacco Board (LKTN)

Additionally, five councils promote Agri commodity products locally and internationally:

Malaysian Palm Oil Council (MPOC)

Malaysian Rubber Council (MRC)

Malaysian Timber Council (MTC)

Malaysia Timber Certification Council (MTCC)

Malaysian Palm Oil Certification Council

![]()

1. Malaysian Palm Oil Board (MPOB)

MoA Signing

MPOB with Panasonic

Palm Based MDF, Panasonic with client

Pocket Talk

Palm Based MDF (Panasonic)

Antibacterial Fabric Softener

Palm-based Polyurethane Adhesives

2. Malaysian Rubber Board (MRB)

Product Demonstration

RRIMPaint – on IBS panel Kenaf

RRIMColour – on drawing paper and canvas

3. Malaysian Timber Council (MTC) / Malaysian Timber Industry Board (MTIB)

Perfume Making Demonstration

How to make base perfume using Oudh Perfume

Explores new market opportunities

Displays Product Sample in Innovating Sustainability Through Bamboo Technology

Eg: building materials, furniture and air filtration

4. Malaysia Cocoa Board (LKM)

Product Launching and Demonstration

Products from Le Bourne

5. Malaysia Pepper Board (MPB)

Cooking Demo

6. National Kenaf and Tobacco Board (LKTN)

Product Demonstration & Promotion

BioKenaf Tea

Oriented Strand Board (OBS)

7. Malaysian Palm Oil Council (MPOC)

Pocket Talk

Red Palm Oil

Cooking Demo

Live cooking demo using palm oil

Upin & Ipin Meet and Greet

Promotes palm oil education

8. Malaysian Rubber Council (MRC)

Live Performance

Product Display

Biodegradable Glove, High Damping Natural Rubber Bearing (HDNRB), Green Precured Tread

9. Malaysian Sustainable Palm Oil (MSPO)

Pocket Talk

MOU signing

![]()

The event showcases groundbreaking innovations and sustainable advancements across Malaysia’s key agricultural industries, featuring collaborations, product demonstrations and educational sessions. The Malaysian Palm Oil Board (MPOB) marks a significant milestone with the signing of a Memorandum of Agreement (MoA) with Panasonic, focusing on palm-based Medium-Density Fibreboard (MDF) and its applications, including antibacterial fabric softeners and palm-based polyurethane adhesives. MPOB also hosts insightful Pocket Talks on industry trends. Meanwhile, the Malaysian Rubber Board (MRB) demonstrates RRIMPaint on IBS Kenaf panels and RRIMColour on various surfaces, highlighting the versatility of rubber-based coatings. The Malaysian Timber Council (MTC) and Malaysian Timber Industry Board (MTIB) present a perfume-making demonstration using Oudh Perfume, opening new market opportunities, while also displaying innovative bamboo-based products for sustainability. The Malaysia Cocoa Board (LKM) introduces new cocoa-based products by Le Bourne, and the Malaysia Pepper Board (MPB) engages visitors with a live cooking demo. The National Kenaf and Tobacco Board (LKTN) promotes BioKenaf Tea and Oriented Strand Board (OSB). Additionally, the Malaysian Palm Oil Council (MPOC) hosts a Pocket Talk on Red Palm Oil, live cooking demonstrations, and an Upin & Ipin Meet and Greet to educate young audiences. The Malaysian Rubber Council (MRC) captivates attendees with live performances and showcases eco-friendly rubber innovations like biodegradable gloves and high-damping natural rubber bearings.

![]()

9 – 15 June 2025 (10:00am – 9:00pm)

![]()

Malaysia Pavilion

COMMODITY INTRODUCTION

Background

Introduced to Malaysia in the early 1870s, as an ornamental plant, commercial planting began in 1917. By the 1960s, oil palm had emerged as a cornerstone of Malaysia’s agro-economic development, providing income, jobs, and export value while uplifting rural communities.

Today, oil palm is Malaysia’s leading agricultural commodity and a major contributor to national export earnings and rural development. The Malaysian Palm Oil Board (MPOB), established on 1 May 2000, is the statutory agency under the Ministry of Plantation and Commodities responsible for the development, research, regulation, and advancement of Malaysia’s oil palm industry.

The oil palm (Elaeis guineensis) is a perennial crop, meaning it produces fruit throughout the year once it reaches maturity. Unlike seasonal crops, oil palm continues bearing for 25 to 30 years, ensuring a stable and continuous supply of raw materials. Its high productivity per hectare makes it the most efficient oil-bearing crop globally, yielding up to 10 times more oil per hectare as compared with soy, sunflower, or rapeseed.

From a single fruit bunch, the oil palm produces two types of oil:

- Crude Palm Oil (CPO): Extracted from the mesocarp (flesh) of the fruit, mainly used in food and cooking applications.

- Palm Kernel Oil (PKO): Extracted from the seed (kernel), commonly used in cosmetics, detergents, and industrial products.

Key Statistics (2024):

- Crude Palm Oil (CPO) Production: 19.34 million tonnes in 2024

- Export Value of Palm Oil and Palm-based products (2024): USD26 billion/ RM109.39 billion in 2024

- Top 10 Palm Oil Export Markets in 2024: India, China, EU, Kenya, Türkiye, Philippines, Pakistan, Japan, Iran, South Korea

Uniqueness and Future Outlook

- Efficient Land Use: Oil palm requires significantly less land to produce the same amount of oil as compared with other oilseed crops.

- Low Input, High Output: Once mature, oil palms require relatively minimal replanting, fertiliser, and pesticides per tonne of oil produced.

- Sustainability Standards: Malaysia has made the Malaysian Sustainable Palm Oil (MSPO) certification mandatory to enhance transparency, traceability, and sustainable practices in the sector.

- Climate Advantage: As a tropical crop, oil palm thrives in Malaysia’s equatorial climate with consistent rainfall and sunlight, enabling year-round harvesting.

- Versatility of Use: Palm oil is used in myriads of products – from cooking oil, margarine, and non-dairy creamers to cosmetics, personal care items, biodiesel, lubricants, animal feed, and emerging pharmaceutical applications.

- Nutritional Benefits: Palm oil is naturally rich in vitamin E tocotrienols and pro-vitamin A (beta-carotene), making it a potential functional food ingredient in health and wellness products.

With growing global concerns about food security, sustainable production, and responsible sourcing, Malaysian palm oil offers a future-proof, science-backed, and environmentally aware solution for consumers and industries worldwide.

INTERNATIONAL EVENT

- MPOB International Palm Oil Congress and Exhibition (PIPOC 2025)

18 - 20 November 2025

Kuala Lumpur Convention Centre (KLCC)

PIPOC 2025 is the flagship biennial event organised by the Malaysian Palm Oil Board (MPOB), bringing together global experts, innovators, industry leaders, researchers, and policymakers in the palm oil and related sectors. Scheduled to take place from 18–20 November 2025 at the Kuala Lumpur Convention Centre (KLCC), this international congress and exhibition serves as a premier platform for knowledge exchange, commercial partnerships, and showcasing cutting-edge research, sustainability practices, and technological advancements in the palm oil industry.

With an expected attendance of over 2,000 delegates from around the world, PIPOC 2025 will feature thematic conferences, scientific presentations, and a vibrant trade exhibition. It aims to promote sustainable solutions, new innovations, and responsible global sourcing to meet the future demands of food, energy, health, and industrial applications.

INTERNATIONAL MARKET OPPORTUNITIES (Focus: Japan & East Asia)

- Japan remains a strategic market, particularly for palm-based food ingredients, frozen foods, confectionery, and oleochemical applications.

- Growing consumer demand for sustainable and certified products in Japan aligns well with MSPO, presenting new opportunities for Malaysian exporters.

- There is also high potential for bilateral collaboration in R&D, halal innovation, and biohealth product development using palm-derived bioactives.

PROPOSED NARRATIVE / KEY MESSAGES

“Palm Oil from Malaysia: A Future-Proof, Sustainable Choice”

The Malaysian oil palm industry offers sustainable solutions for global needs in food, health, and green technology. Backed by scientific research, certified sustainable standards, and industry-wide innovation, ensuring Malaysian palm products are safe, ethical, and of premium quality – well-positioned to meet the expectations of discerning markets such as Japan and across East Asia.

Introduction to the Malaysian Rubber Board (MRB)

The Malaysian Rubber Board (MRB) was established on January 1, 1998, under the Malaysian Rubber Board Act 1996. It is a statutory body under the Ministry of Plantation and Commodities responsible for overseeing the development of the rubber industry in Malaysia, from cultivation, research, processing, manufacturing of rubber products, to marketing.

The primary objective of MRB is to assist in the development and modernisation of the Malaysian rubber industry in all aspects from cultivation of the rubber tree, the extraction and processing of its raw rubber, the manufacturethe marketing of rubber and rubber products.

Since 1998, MRB has comprises three key agencies:

- Rubber Research Institute of Malaysia (RRIM)

- Malaysian Rubber Research and Development Board (MRRDB)

- Malaysian Rubber Eastern Licensing Board (MRELB)

- Malaysia’s Rubber Production and Export Statistics (Up to December 2024)

Natural Rubber (NR) Production

- The total NR production in Malaysia for 2024 is estimated at 350,000 tonnes, showing a slight increase from the previous year.

- In December 2024, NR production declined by 5.1% to 38,299 tonnes compared to November 2024.

Export for Rubber and Rubber Products

- Malaysia’s NR exports in December 2024 increased by 1.8% to 44,338 tonnes compared to the previous month.

- China remains the main export destination for Malaysian NR, accounting for 43.6% of total exports in January 2025.

- Malaysia’s rubber products export surged by 17.6% to RM23.7 billion in 2024 compared to RM20.1 billion in 2023.

- Uniqueness and Future Outlook of Malaysia’s Rubber Industry

Unique Aspects

- Malaysia is well-known for producing Standard Malaysian Rubber (SMR), a technical-grade rubber grading system introduced by RRIM in 1965.

- The country is also a major producer of rubber gloves, accounting for 63% of global rubber glove exports.

Future Outlook

- Malaysia’s rubber industry is expected to experience moderate growth in 2025, driven by increasing NR prices due to reduced oversupply in the glove market.

- The Malaysian Sustainable Natural Rubber (MSNR) initiative, launched on 7 October 2024, aims to ensure the country’s rubber industry complies with international sustainability standards, aligning with the 2030 SDGs and the EU Deforestation Regulation (EUDR).

MRB continues to play a crucial role in steering Malaysia’s rubber industry towards greater sustainability and global competitiveness. With initiatives like MSNR and green technology investments, the industry is well-positioned to face future challenges while maintaining its standing as a global rubber market leader.

Malaysian Sustainable Natural Rubber (MSNR)

Malaysian Sustainable Natural Rubber (MSNR) is a sustainability recognition through regulatory and enforcement approach, which is granted to license and permit holders of the Malaysian Rubber Board, to ensure the sustainability of natural rubber.

Objective of MSNR

To position Malaysia's natural rubber as a competitive and sustainable product in the global market.

Narrative for MSNR - Malaysian Sustainable Natural Rubber

Malaysia has long stood as a global leader in the rubber industry. From the early days of rubber plantations to the modern era of industrial-scale production, rubber has played a pivotal role in shaping the nation's economy. But as we move forward, the focus has shifted from mere production to responsible and sustainable practices. This is the foundation of the Malaysian Sustainable Natural Rubber (MSNR) initiative.

MSNR is more than just rubber. It is a comprehensive initiative that embodies Malaysia’s commitment to aligning the rubber industry with global sustainability standards. It is about producing high-quality rubber while preserving the environment, protecting biodiversity, and ensuring the well-being of rubber smallholders, industries and communities.

At the heart of MSNR is the integration of sustainable agricultural commodity practices, MSNR is transforming the way rubber is cultivated and processed from upstream sector to midstream sector. The initiative also leverages green technology to minimize waste, reduce carbon emissions, and promote circular economy principles throughout the supply chain.

But sustainability is not just about environmental impact. MSNR also addresses the socio-economic dimension by empowering rubber smallholders through integration of Malaysian law and regulations, high quality raw materials and community support programs. By creating a more equitable and sustainable rubber industry, MSNR ensures that the benefits of economic growth are shared by all.

Malaysia’s rubber has been a symbol of strength and resilience for over a century. Now, with MSNR, it is set to become a global benchmark for sustainable natural rubber. It is not just about keeping up with global requirement for Sustainable Development Goals (SDG) and the EU Deforestation Regulation, it is about setting new standards for sustainability, innovation, and social responsibility.

Join us in supporting MSNR. Because our rubber is not just a product, it is a legacy, a commitment to a greener and more sustainable future.

RRIMColor

RRIMColor™: Colors of Life, A Touch of Timeless Art

In Japan, art is more than just expression it's a legacy of the soul, passed down through generations. From traditional Ukiyo-e paintings to tranquil Zen gardens, every shade holds meaning, emotion, and peace especially for the elderly who see the world through a lens of deep beauty and cherished memories.

This is where RRIMColor™ comes in a Malaysian natural rubber-based paint innovation that reimagines art in a new, lasting, and meaningful way. Designed especially for those who value calm, comfort, and the beauty of life through color.

Soothing Colors That Speak to the Soul

- Soft, Classic Tones Inspired by Nature

RRIMColor features a palette inspired by Japan’s serene beauty sakura pink, Kyoto forest green, and the calm blue seas of Shikoku. These gentle colors do more than beautify a space, they create a peaceful atmosphere, perfect for the elderly and the mindful.

- Silky Texture, Elegant Finish

Made with micro-particle rubber technology, RRIMColor offers a soft, matte finish that minimizes glare. It’s ideal for homes, art spaces, care centers, and places of reflection or worship.

- Long-Lasting Shades, Like Lasting Memories

RRIMColor is built to preserve beauty over time. Its special formula resists stains, moisture, and weather changes keeping colors vivid and meaningful for years to come, just like precious memories.

- Safe for Health and the Environment

Low in VOCs and free from heavy metals, RRIMColor ensures fresher indoor air, less chemical odor, and a safer environment especially important for elders with sensitivities.

- Celebrating Art, Honoring Life

For Japan’s elderly, color brings emotion and nostalgia. RRIMColor is not just paint it’s a tribute to art, serenity, and the quiet joy of everyday life like the warmth of a village in Nara or the calm of a Kyoto teahouse.

From Traditional Homes to Art Spaces, RRIMColor™ Enriches Every Corner

Whether it’s a heritage home, a community hall, gallery, or care center, RRIMColor brings more than just color. It brings soul, stories, and serenity, treasured across generations.

RRIMColor – Color That Breathes Art, Color That Touches the Heart

RRIMPaint: Innovative Rubber-Based Paint for Maximum Protection!

RRIMPaintTM: A Natural Latex-Based Paint Innovation for Eco-Friendly and Sustainable Protection!

Imagine a world where paint is not just a color but a protective shield for homes, buildings, and even the environment. Introducing RRIMPaintTM, an innovative paint made from natural rubber latex that offers exceptional durability while promoting sustainability in both the environment and Malaysia’s rubber industry.

Superior Protection for Homes & Buildings

- Waterproof & Moisture-Resistant

RRIMPaintTM forms a waterproof barrier that prevents moisture absorption, making walls more durable and reducing the risk of mold and weather-related damage. - Crack-Resistant & Flexible

The natural elasticity of rubber allows RRIMPaintTM to adapt to temperature changes, minimizing the risk of cracks in walls and building structures. - Heat-Absorbing & Cooling Effect

The special formula in RRIMPaintTM reduces heat absorption, naturally cooling homes and buildings, saving on energy costs and electricity bills. - Stain-Resistant & Easy to Clean

With its anti-stain and oil-resistant properties, RRIMPaintTM is ideal for both indoor and outdoor spaces, making it the perfect choice for homes, offices, schools, and shelters. - Eco-Friendly & Low VOC

Low in volatile organic compounds (VOCs), free from mercury, cadmium, and lead, RRIMPaintTM is a safer choice for health and the environment. Ideal for shelters, community centers, and hospitality spaces that require cleaner air quality.

RRIMPaintTM – The Ideal Choice for Home & Workspace Protection

From residential homes to shelters, community centers, schools, and hospitals, RRIMPaintTM provides not just vibrant colors but long-term protection against the elements.

RRIMPaintTM – The Color of Innovation, The Color of the Future!

The Global Paint Industry: A Strategic Perspective

The global paint industry has experienced significant growth in recent years. In 2022, the global paint resin market reached a value of USD 52.99 billion, with the Asia-Pacific region holding the largest market share at 43.8%. - Source: CHINA TCCHEM

Moreover, the protective coatings market, such as 72-inch paint protection films, was estimated to be worth USD 18.1 million in 2024 and is projected to

grow at a compound annual growth rate (CAGR) of 5.5% from 2025 to 2030. - Source: GRAND VIEW RESEARCH

Looking ahead, the global paint industry is expected to continue its robust growth trajectory over the next five years, from 2025 to 2030. According to a report by Grand View Research, the global paint and coatings market is forecasted to reach USD 207.7 billion in 2025, with a CAGR of approximately 5.4% from 2025 to 2030.

This growth is driven by rising demand in the construction and automotive sectors, as well as increasing consumer preference for eco-friendly, high-performance products.

While specific data on the rubber-based paint market remains limited, innovations such as RRIMPaint and RRIMColor by the Malaysian Rubber Board have the potential to leverage these emerging trends.

By emphasizing features such as sustainability, low VOC content, and enhanced durability, rubber-based products could attract a market that is increasingly focused on environmental responsibility and health considerations.

Overall, with a strategic marketing approach and a focus on the unique benefits of rubber-based coatings, there is significant potential to penetrate and expand within the competitive global paint market, particularly in the rapidly growing Asia-Pacific region.

INTRODUCTION

The timber industry remains as a key driver of Malaysia’s economic growth, having evolved from a traditional exporter of tropical logs to a global supplier of high value-added timber products. This sector continues to undergo dynamic changes and faces complex challenges, both domestically and internationally. In addition to palm oil and rubber, the timber industry plays a significant role in driving Malaysia’s agricommodity export growth, contributing 12.28% to the sector’s total export value of RM186.54 billion in 2024.

Despite uncertainties in the global economy, Malaysia has maintained its position as a major player in the international timber and timber products market. In 2024 alone, timber exports were valued at RM22.92 billion, which is a remarkable achievement that reinforces the country’s standing as one of the world’s leading exporters of premium-quality timber products. Major export products include furnitures worth RM9.89 billion (43% market share), plywood RM2.40 billion (11% market share), sawntimber RM2.05 billion (9% market share) and builder’s and joinery carpentry RM1.32 billion (6% market share).

In response to the challenges faced by the timber industry, the Malaysian Timber Industry Board (MTIB) has implemented several strategic measures, including the enhancement of the Malaysian Timber Legality Assurance System (MyTLAS) as a guaranteed timber and timber products produced with legal timber status from Peninsular Malaysia. Similar measures were implemented by Sabah and Sarawak using the Sabah Timber Legality Assurance System (SabahTLAS) and Sarawak Timber Legality Verification System (STLVS). MTIB is committed to raising industry awareness on the importance of Environmental, Social and Governance (ESG) compliance through targeted training and workshop. To address the issue of raw material shortages and to promote value-added production, MTIB encourages innovation and the utilization of alternative materials, such as wood plastic composites (WPC) and oil palm trunk (OPT) in addition to traditional value-added products such as furniture, plywood, sawntimber, builder’s joinery carpentry and others. These initiatives are designed to ensure the long-term sustainability, competitiveness and global relevance of Malaysia’s timber industry.

CURRENT PROMOTIONAL INITIATIVES

Programmes that will be carried out by Malaysian Timber Industry are as follows:

- Pocket Talk on “What You Need to Know About Sustainable Timber from Malaysia” by MTIB, MTC and MTCC

- Demonstration of Malaysian Wood Carving and Related Matters

- DIY an Oudh Perfume Demonstration

- Innovating Sustainability Through Bamboo Technology by Showcasing Bamboo-Based Products for Shelter

INTERNATIONAL MARKET OPPORTUNITIES, ESPECIALLY IN JAPAN AND THE EAST ASIA REGION:

Japan ranks as third-largest market for Malaysian timber and timber products valued at RM2.85 billion in 2024, after the USA and China. Major products exported to the market are plywood, furniture and fibreboard. Meanwhile, imports from Japan to Malaysia consists of furniture, builders’ joinery and carpentry and fibreboard which valued at RM109.7 million in 2024.

The Clean Wood Act, enforced by Japan in 2017, encourages businesses to use legally harvested wood and wood products by verifying their legality through due diligence. In response, Malaysia’s TLAS serves as a national framework that assures the legality of timber products exported from Malaysia through a system of compliance with legal requirement related to harvesting, transportation and trade along the supply chain. As TLAS aligns with the provisions of the Clean Wood Act, Malaysian timber exporters are well-positioned to access and compete in the Japanese market. This mutual recognition strengthens bilateral trade, promote good forest governance and reinforces both countries’ commitment to sustainable forest management, combating illegal logging and responsible trade practices.

Japan is witnessing a growing trend in the construction of mid-rise buildings using timber materials. The Public Buildings Wood Use Promotion Act in Japan, officially titled the "Law on Promotion of Use of Wood in Public Buildings," aims to increase the use of wood in public buildings came into effect on 1 October 2021. The Act obligates national and local governments to use wood in public buildings, particularly those with three stories or less. The increasing growth of the timber construction industry is a positive trend, both from an economic and ecological perspective. Furthermore, there is an increase in demand for structures made of energy-efficient, sustainable and carbon-neutral materials due to growing concerns about climate change. As one of the top exporters of plywood to Japan, there remains significant potential for Malaysian exporters to further explore and expand their presence in the Japanese market, both to enhance bilateral trade performance and to meet the growing demand for plywood.

Neighbouring countries like China, South Korea and Taiwan aalso present huge potential markets as they recorded as the second, 12th and 13th important export market for Malaysia worth RM3.4 billion, RM396.1 million and RM359.1 million in 2024.

PROPOSED NARRATIVE OR KEY MESSAGE:

Demonstration of Malaysian Wood Carving and Related Matters

Narrative: The art of wood carving plays an important role in beautifying government buildings, strengthening cultural heritage, and promoting traditional aesthetic values. The exhibition aims to showcase the art and culture of Malay heritage in Malaysia.

DIY an Oudh Perfume Demonstration

Narrative: Locally known as Gaharu or Karas, agarwood is now being recognized as an valuable non-timber forest product. It was used hundreds of years ago as medicine and basic material to produce perfumes. Today, agarwood is being traded in more than 18 countries with trade worth millions of US dollars annually. Indeed, due to the growth in the population and affluence of gaharu-consuming markets, the demand for gaharu has risen significantly over the past 30 years.

This segment will demonstrate the process of creating a base perfume using Oudh Perfume. Participants will learn how to mix essential oils to craft their own signature fragrance. The perfume they create will serve as a souvenir, offering them a personal gift to take home.

Program Innovating Sustainability Through Bamboo Technology by Showcasing Bamboo-Based Products for Shelter

Narrative: Showcasing sustainable bamboo solutions by highlighting its potential in building materials, furniture, air filtration, and insulation. As the world shift toward greener alternatives, bamboo stands out as a renewable, high-performance material that can substitute wood, plastics and synthetic fibres.

At the exhibition, visitors will have the opportunity to explore bamboo fibres and products, such as non-woven fabric and composites, through interactive displays and product samples.

With increasing demand for eco-friendly solutions, this industry aims to scale its innovations globally, driving market growth and investment opportunities.

Introduction to the Commodity

(Brief background / latest production and export statistics / uniqueness / future outlook)

The cocoa industry in Malaysia began to grow rapidly in the 1970s and 1980s, making it one of the country’s key commodities alongside palm oil and rubber. At that time, cocoa cultivation was widespread, especially in Sabah, Sarawak, and several states in Peninsular Malaysia. However, since the late 1990s, the industry has experienced a significant decline in planted area and production due to competition from more profitable commodities and issues related to low yield returns.

Malaysia subsequently shifted its industry strategy by focusing on midstream cocoa processing and the production of downstream finished products. This aligns with the growing global demand for cocoa grinding and the production of value-added products such as cocoa butter, cocoa powder, cocoa mass, and chocolate.

Malaysia currently has a cocoa grinding capacity of 368,000 tonnes per year and ranks as the 5th largest cocoa grinder in the world, contributing approximately 7.5% to global grinding output.

The main exported products include cocoa butter, cocoa mass, cocoa cake, cocoa powder (both sweetened and unsweetened), and chocolate. In 2024, Malaysia’s cocoa industry recorded an impressive performance, with export values reaching RM15.06 billion—a significant increase of 83.66% compared to RM8.20 billion the previous year. Malaysian cocoa products are exported to over 200 destinations, including the United States, Japan, China, and Singapore.

The cocoa industry has also made a significant impact by contributing to the nation’s economic development. In 2024, the cocoa sector is projected to contribute RM2.378 billion to the Gross Domestic Product (GDP), with more than 22,000 individuals involved in the industry’s value chain. This includes smallholders, grinders, chocolate manufacturers, and artisanal chocolate entrepreneurs.

The uniqueness of Malaysia’s cocoa industry lies in its ability to develop a complete value chain—from farm to finished products such as handmade chocolates—while also adhering to halal standards and international quality benchmarks.

CURRENT PROMOTIONAL INITIATIVES

(Including ongoing or upcoming programmes/campaigns)

Among the promotional programmes and activities organized by the Malaysian Cocoa Board (MCB) in 2025 are:

International Exhibitions:

- Expo 2025, 8–12 June 2025 in Osaka, Kansai, Japan

- ANUGA Food and Beverage Fair 2025, 4–8 October 2025, Messe Cologne, Germany

Domestic Exhibitions:

- Malaysian International Cocoa Exhibition 2025 (MICE 2025),

24–27 May 2025, Sabah International Convention Centre (SICC), Kota Kinabalu, Sabah

(includes Business Opportunity sessions and Pocket Talk presentations)

- Pastry & Cocoa Festival (PCF), 5–7 September 2025,

Sunway Pyramid Convention Centre, Kuala Lumpur – Principal Partner with Tastefully Malaysia Sdn Bhd

- Food & Drinks Malaysia by SIAL (FDM 2025), 1–3 July 2025,

Malaysia International Trade and Exhibition Centre (MITEC), Kuala Lumpur, Malaysia

- Malaysian International Halal Showcase (MIHAS), 17–20 September 2025,

Malaysia International Trade and Exhibition Centre (MITEC), Kuala Lumpur, Malaysia

Cocoa Business Matching Programmes – Domestic & International:

- Cocoa Business Matching (CBM) in conjunction with the Malaysian International Cocoa Exhibition (MICE 2025)

- Cocoa Business Matching in conjunction with the Pastry & Cocoa Festival (PCF)

- International Cocoa Business Matching in conjunction with Salon du Chocolat, Malaysia

Digital Cocoa Marketing Programme:

- Digital cocoa marketing via the TikTok Malaysia e-commerce platform

INTERNATIONAL MARKET OPPORTUNITIES, ESPECIALLY IN JAPAN AND THE EAST ASIA REGION:

International markets, particularly Japan and the East Asia region such as China and South Korea, are among the major importers of Malaysian cocoa products and offer tremendous potential for the expansion of Malaysia’s cocoa industry. Japan remains one of Malaysia’s key trading partners in the cocoa trade, especially for semi-finished cocoa products.

Malaysia has been exporting cocoa beans and various cocoa-based products to Japan for several decades. In the early 1990s, exports to Japan were limited to cocoa beans and cocoa mass only. However, in line with the industry’s advancement and Japan’s increasing emphasis on processing quality, Malaysia has expanded its exports to include a broader range of semi-finished and finished cocoa products.

In 2024, the total value of Malaysia’s cocoa and cocoa product exports to Japan reached RM1.39 billion, marking an increase of 85.6% compared to RM746.28 million in the previous year. The main products exported to the Japanese market included cocoa butter valued at RM699.95 million, cocoa powder (both sweetened and unsweetened) at RM283.39 million, and cocoa mass amounting to RM144.09 million.

This surge in demand highlights Japan’s strong interest in Malaysian cocoa products, which meet high standards and quality assurance.

PROPOSED NARRATIVE OR KEY MESSAGE:

The participation of the Malaysian Cocoa Board and the cocoa industry in World Expo 2025, Osaka, is aimed at showcasing Malaysia’s premium and high-quality cocoa products, as well as enhancing business networking with buyers from Japan.

The products presented include single-origin chocolates made from Malaysian cocoa beans renowned for their superior flavour, with processing that is quality-assured and complies with food safety standards.

PROMOTING MALAYSIAN PEPPER TO THE WORLD

Expo 2025 Osaka, Kansai provides a good opportunity for Malaysia to expand and find new markets for its Agri-commodity exports, particularly in the pepper sector. Malaysia will showcase and promote its sustainable initiatives and management vital to ensure Agri-commodity continues to be one of the main pillars of its economy.

For decades, pepper has been a significant cash crop, especially in Sarawak, supporting the livelihoods of many rural communities. Currently, there are approximately 39,293 pepper farmers in Sarawak cultivating around 8,289 hectares of pepper, representing about 98% of Malaysia's total pepper farmers and cultivation area. This connects pepper cultivation to the traditional agricultural lifestyle of many communities in the state, particularly the Iban and Bidayuh people who constitute a large percentage of pepper farmers.

The Malaysian pepper industry contributed RM2,272 million of the nation's GDP in 2024. Currently, Malaysia ranks No.5 based on world pepper production 2024 among IPC countries. About 70 % of Sarawak's pepper is exported as whole black pepper and the remaining as white pepper, green pepper in brine, value-added pepper and pepper products.

In 2024, Malaysia exported 5,753 tonnes of pepper valued at RM186.68 with Sarawak being the primary contributor. This global recognition and economic reliance links pepper to the state's identity and agricultural heritage.

While not every single local dish prominently features white pepper, its high quality and unique flavour make it a prized ingredient in both home cooking and more refined Sarawakian cuisine. It is used to add a subtle heat and aromatic complexity to various dishes, especially those where a clean pepper flavour is desired over the bolder, earthier notes of black pepper.

MALAYSIA ON MARKET STRENGTH

Japan is fully dependent on imports for pepper with an annual consumption and demand of about 25,000 tons. Japan’s culinary traditions value high-quality ingredients, and pepper is widely used in Japanese cuisine and food processing, particularly in seasoning and flavouring. There is a growing demand for premium spices, including pepper, in food production, health products, and gourmet cooking. Malaysia’s ability to supply high-grade, traceable, and certified pepper gives it an advantage in the Japanese market, which is sensitive to quality.

Saraspice Sdn Bhd (SSB), a subsidiary company owned by the Malaysian Pepper Board (MPB), plays a crucial role in promoting the Sarawak pepper industry, both domestically and globally. Recent successes such as listing Saraspice pepper products on AirAsia international and domestic flights, increase global brand recognition, which indirectly benefits its use in international cuisines, including potentially in innovative and fine dining establishments seeking unique, high-quality spices.

Furthermore, MPB's efforts in research and development including exploring various applications of pepper and several participations in international trade events, also contribute to showcasing the versatility and premium quality of Sarawak white pepper to a global culinary audience.

CORPORATE INFORMATION

Recognizing the significant contribution of the pepper industry to the country’s economy, the Malaysian government has put further initiative for the growth of the industry by establishing the Malaysian Pepper Board (MPB). Since 2007, MPB is under the purview of the Ministry of Plantation and Commodities (KPK). MPB aims to further strengthen the development of the industry which covers growing and production, extension, research and marketing. Under the Geographical Indications Act 2000, Sarawak Pepper has been registered as Geographical Indication awarded to the Malaysian Pepper Board (MPB) since 2003. For more info visit our website at www.mpb.gov.my

ACTIVITIES ON WEEK 9

MOU BETWEEN SARASPICE SDN BHD AND VOX TRADING CO. LTD.

MOU focuses on exploring collaborative efforts to promote the sustainable supply of Sarawak black pepper to Vox Trading Co., Ltd. Key areas of collaboration include ensuring sustainable demand at competitive prices, sharing market information—particularly related to Japanese market requirements—undertaking joint initiatives such as training, advisory support, and provision of farm implements to pepper farmers, as well as other mutually agreed activities.

DEMO COOKING BY CHEF

This recipes embody the versatility and the uniqueness of the world renowned Sarawak Pepper in the Culinary World. Together with Chef Razak Abdullah have created and tested numerous recipes ranging from appetizers, to entrée and from side dishes to desserts.

The uniqueness of Sarawak Pepper adds to your dishes starts with the aroma to what your appetite to the lingering flavour that works wonders on your palate. The use of Sarawak Pepper in your cooking extends far beyond the recipes that we have concocted for you. It is only limited by one’s imagination whilst we taste the Sarawak Pepper in our food and we can easily imagine the loosing care that thousands of rural farmers have puts in growing and harvesting this spice and make its an indispensable part of our culinarydelight.

We hope you enjoy trying these recipes as much as we at Malaysian Pepper Board and Chef have prepared and presented to you in this cooking demo. Always insist on Sarawak Pepper!

PRODUCT DISPLAY

EXPERIENCE THE FINEST OF SARAWAK PEPPER WITH SARASPICE

Renowned globally for its superior taste and aroma, Saraspice Black Pepper and White Pepper deliver an unparalleled culinary experience. Sourced exclusively from genuine Sarawak farmers, every grain of our pepper embodies the dedication and tradition of Sarawak’s rich agricultural heritage.

INTRODUCTION (KENAF)

Kenaf (Hibiscus cannabinus) is a versatile, fast-growing plant cultivated for its fibres and seeds. Originally from Africa and South Asia, it was introduced in Malaysia as part of the government’s initiative to diversify agricultural commodities and replace tobacco, which has seen a decline due to market and health concerns. Kenaf is currently regulated under the National Kenaf and Tobacco Board (LKTN).

Kenaf is a fast-growing, eco-friendly crop that matures in just four to five month. It produces strong, lightweight fibre used in construction, automotive parts, paper, and biodegradable products. As a sustainable plant, it absorbs high levels of CO₂ and grows well on marginal land with minimal inputs, making it ideal for green industries and low-impact farming.

The global kenaf market is experiencing significant growth, driven by increasing demand for sustainable and eco-friendly materials. Japan, in particular, is emerging as a key player in this market. In 2024, Malaysia’s kenaf industry demonstrated steady growth with 1,614 hectares under cultivation, supported by 796 growers, and generating a total sales value of RM14.81 million. This performance highlights kenaf's role in supporting rural livelihoods, green industrial development, and national sustainability goals.

The global kenaf market is projected to reach approximately USD 7.85 billion by 2025, with the Asia Pacific region accounting for 32.79% of the market share. Within Asia Pacific, Japan holds a 10.53% share, indicating its significant role in the market. Kenaf is a prominent component in the natural fiber composites market, which is expected to grow from USD 328 million in 2023 to USD 424 million by 2028, at a CAGR of 5.3%. Kenaf composites are particularly valued in the automotive industry for their strength, light weight, and sustainability. The demand for kenaf is expected to continue growing globally, with Japan playing a pivotal role in this expansion. The country's focus on sustainability, innovation in automotive and construction sectors, and increasing consumer preference for eco-friendly products as key factors driving the adoption of kenaf-based materials. As industries seek alternatives to traditional materials, kenaf's rapid growth cycle, versatility, and environmental benefits position it as a valuable resource for the future.

CURRENT INITIATIVE / PROGRAMME

The National Kenaf and Tobacco Board (LKTN) is currently spearheading a multi-faceted initiative to bolster the kenaf industry in Malaysia. A key aspect of this effort involves the recent introduction of two new climate-resilient kenaf seed varieties, MK1 and MK2, developed in collaboration with Nuklear Malaysia. These varieties, resulting from gamma irradiation technology, promise significantly higher yields and possess distinct physical characteristics, marking a substantial advancement over existing options. Complementing this agricultural innovation is the development of a comprehensive five-year strategic plan, spearheaded by the Ministry of Plantation and Commodities in conjunction with LKTN.

This plan aims to elevate kenaf to the status of a major commodity, emphasizing value-added product development and establishing a strong "Malaysian-made" identity. Recognizing the current lack of a complete industry ecosystem, especially in processing and manufacturing, LKTN is actively exploring best practices from established kenaf-exporting nations to guide the development of local processing capabilities and attract investment. Simultaneously, LKTN is actively promoting the diverse commercial applications of kenaf, ranging from textiles to pet food, to both tobacco growers seeking alternative crops and the broader private sector. This is coupled with ongoing government support, including financial incentives and assistance for smallholders, aimed at fostering a robust and thriving kenaf industry across Malaysia.

NARRATIVE PROPOSAL

“Kenaf: Malaysia’s Green Innovation – Building Sustainable Futures from Seed to Market.” Malaysia is pioneering the future of bio-based industries through kenaf—a versatile and sustainable crop driving innovation across construction, textiles, nutrition, and lifestyle. As global markets shift toward eco-conscious solutions, Malaysia presents a complete kenaf value chain powered by innovation, policy support, and regional expertise.

KENAF IBS BY TASBLOCK SDN. BHD.

At the forefront of sustainable construction, Tasblock Sdn. Bhd. presents its pioneering Kenaf Industrialized Building System (IBS). This innovative approach integrates kenaf, a rapidly renewable resource, into a modular construction framework, offering significant advancements in efficiency and environmental responsibility. Tasblock's Kenaf IBS streamlines building processes, enabling faster assembly, reduced on-site waste, and the creation of high-performance structures with a lower carbon footprint. This Malaysian-developed technology exemplifies the convergence of agricultural innovation and advanced construction techniques, providing a compelling solution for a greener built environment and underscoring Malaysia's commitment to sustainable development within the global construction sector.

Technical Textiles: Enabling next-generation automotive, aerospace, and industrial applications with high-performance natural fibres.

KENAF IBS BY VCI SDN. BHD.

Vertex Central Industries Sdn. Bhd. (VCI) is pioneering a sustainable future in construction with its innovative kenaf-based Industrialized Building System (IBS). By harnessing the inherent properties of kenaf, a fast-growing and environmentally friendly crop, VCI is transforming the way buildings are conceived and constructed. Their advanced IBS offers a compelling alternative to conventional methods, promising accelerated construction timelines, superior thermal and acoustic insulation, and a significant reduction in environmental impact through the utilization of bio-based materials. VCI's commitment to research and development has yielded a system that not only meets stringent building standards but also champions ecological responsibility. As Malaysia advances towards a greener economy, VCI's kenaf IBS stands as a testament to the nation's ingenuity in leveraging natural resources for cutting-edge, sustainable building solutions, offering a glimpse into the future of construction.

BIOKENAF TEA BY AURA-BIOCARE SDN. BHD.

Bio-Aura, in strategic collaboration with Universiti Malaysia Kelantan, proudly presents Biokenaf Tea, a functional beverage that encapsulates the potent health benefits of kenaf. This innovative tea is a testament to the synergistic power of scientific research and natural resources, meticulously developed to harness kenaf's rich profile of antioxidants and bioactive compounds. Biokenaf Tea offers a unique and palatable way to incorporate the health-enhancing properties of kenaf into daily life, potentially supporting overall health and vitality. This collaboration underscores Malaysia's commitment to exploring the nutritional potential of its agricultural biodiversity, transforming kenaf from a versatile fiber crop into a value-added functional food product for health-conscious consumers worldwide.

HOME FURNISHING PRODUCTS BY EADECO NON-WOVEN SDN. BHD

Eadeco Non-Woven Sdn. Bhd. presents its pioneering kenaf mattress at Expo Osaka 2025, showcasing a commitment to sustainable and comfortable sleep solutions. Utilizing advanced non-woven technology, this mattress leverages the inherent breathability, resilience, and moisture-wicking properties of kenaf, a rapidly renewable resource cultivated in Malaysia. The result is a high-quality sleep surface that promotes restful sleep while minimizing environmental impact. Eadeco's innovative approach underscores the potential of natural fibers in creating superior home essentials, offering a compelling example of Malaysian ingenuity in sustainable product development for the global market.

KENAF ORIENTED STRAND BOARD (OSB)

Kenaf Oriented Strand Board (OSB), a sustainable building material developed in collaboration with UiTM. This high-performance alternative to traditional wood panels is made from the fast-growing kenaf plant, offering strength, stability, and durability for various construction uses. This initiative highlights Malaysia's commitment to green building through research and the innovative use of its natural resources.

From engineered structures to wellness and design, kenaf is shaping industries for a cleaner, smarter world. Malaysia welcomes international partners to co-create, co-invest, and co-innovate in the growing global kenaf economy.

COMMODITY INTRODUCTION

Japan is a major consumer of oils and fats, with a population of approximately 123.8 million and a stable per capita consumption of 21.1 kilograms as of 2024. Due to limited domestic agricultural resources, the country’s local production—totaling around 1.75 million tonnes in 2024—primarily consists of rapeseed oil (905,000 tonnes), soybean oil (479,000 tonnes), sesame oil, and corn oil.

Japan relies heavily on imports to supplement its supply, particularly for products such as palm oil (654,900 tonnes), palm kernel oil (78,000 tonnes), and coconut oil (39,000 tonnes). Total domestic consumption reached 2.61 million tonnes, with palm and rapeseed oils being the most widely used.

Japan is a stable market for Malaysian palm oil. In 2024, Japan imported 602,638 tonnes of Malaysian palm oil which gives Malaysia a 92% share of palm oil imports in Japan. In terms of total palm oil and palm-based products, Malaysia exported 2.13 million metric tonnes (MT) of palm oil and palm-based products to Japan, valued at approximately RM5 billion. The primary palm oil products exported include RBD palm olein and RBD palm oil, which together accounted for 62% of total palm oil exports to Japan. Additionally, Japan imported approximately 1.2 million MT of palm kernel shell (PKS) in 2024, equivalent to RM586 million in trade value.

CURRENT PROMOTIONAL INITIATIVES

Following MPOC’s participation in COSME Week Tokyo 2024, one of the key promotional focuses has been the introduction and promotion of red palm oil and tocotrienols to the Japanese market. These components, rich in antioxidants and vitamin E, have attracted attention for their potential benefits in skincare and health supplements. However, consumer awareness and industry understanding of red palm oil and tocotrienols remain relatively limited in Japan.

To strengthen market penetration, ongoing efforts are needed to enhance visibility through targeted campaigns, strategic partnerships with Japanese cosmetic and nutraceutical companies, and educational outreach targeted at both consumers and formulators. Expanding this initiative across trade shows, digital media, and direct engagement can help position Malaysian palm oil as a premium, functional ingredient aligned with Japan’s growing demand for natural and science-backed wellness products.

INTERNATIONAL MARKET OPPORTUNITIES

Key future opportunities include:

- Red Palm Oil Promotion: There is potential to introduce and promote red palm oil in the Japanese market by increasing consumer awareness of its health benefits, particularly its high antioxidant and vitamin A content.

- Growth in the Food Manufacturing Industry: Japan’s expanding food manufacturing sector presents increased demand for palm oil as an essential raw material, especially in products like margarine, shortening, and instant noodles.

- Biomass Energy Expansion:

- The growing number of biomass power plants in Japan under the FIT scheme creates further demand for palm stearin and PKS as feedstock.

- A growing trend toward long-term supply contracts is ensuring stable demand for sustainable biomass materials from Malaysia.

- Halal Market Collaboration:

- In May 2024, Malaysia and Japan engaged in bilateral discussions to strengthen cooperation in the halal trade segment.

- The establishment of the Japan Food Export Platform in Malaysia aims to assist Japanese companies in navigating the halal certification process and expanding halal-compliant product lines using palm-based ingredients.

- Sustainability & Certification Opportunities:

- With Japan's increasing focus on environmental sustainability, there is growing demand for MSPO-certified palm oil products.

- Malaysian exporters can capitalize on this trend by aligning supply chains with Japan’s environmental and traceability standards.

PROPOSED NARRATIVE OR KEY MESSAGES TO BE HIGHLIGHTED TO INTERNATIONAL VISITORS

- Sustainably Produced

- Malaysian palm oil is certified under the MSPO (Malaysian Sustainable Palm Oil) standard, ensuring safe, responsible, and eco-friendly production.

- Efforts include protecting forests, reducing carbon emissions, and supporting local communities.

- Good for Health

- Rich in vitamin E tocotrienols and beta-carotene, palm oil supports heart, brain, and immune health.

- Red palm oil is a natural source of important nutrients.

- Used in Everyday Products

- Palm oil is found in cooking oils, snacks, cosmetics, soaps, and even eco-friendly fuels.

- It’s a key ingredient in many products people use daily.

INTRODUCTION

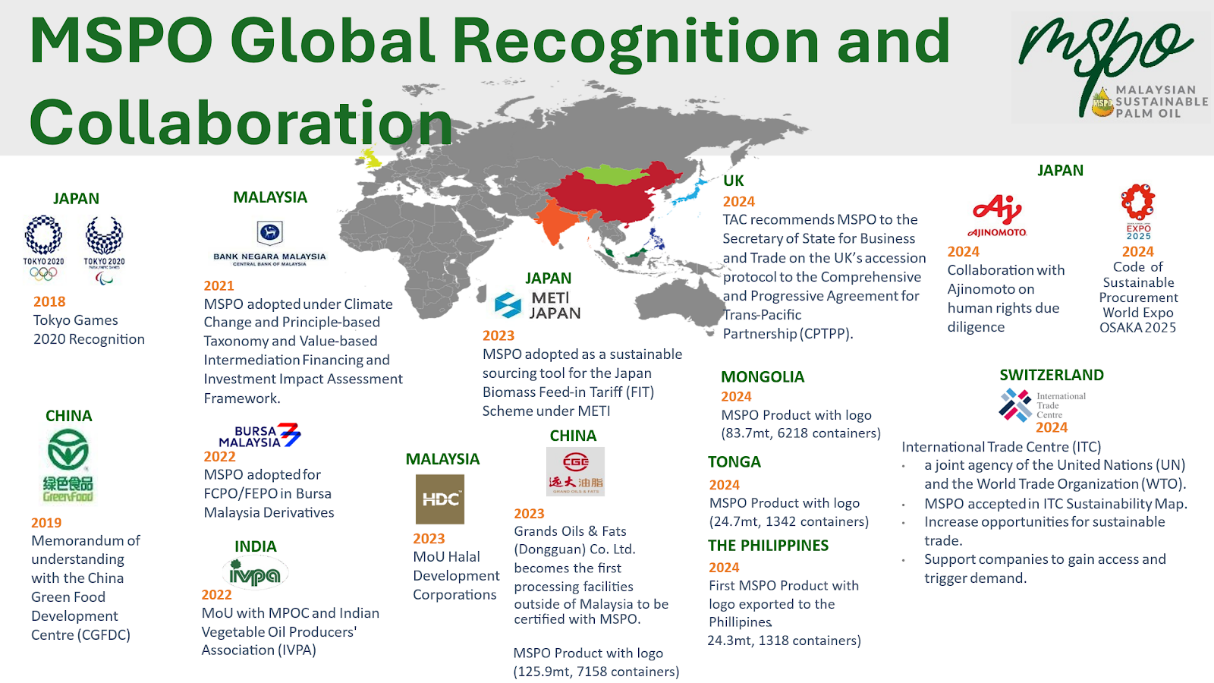

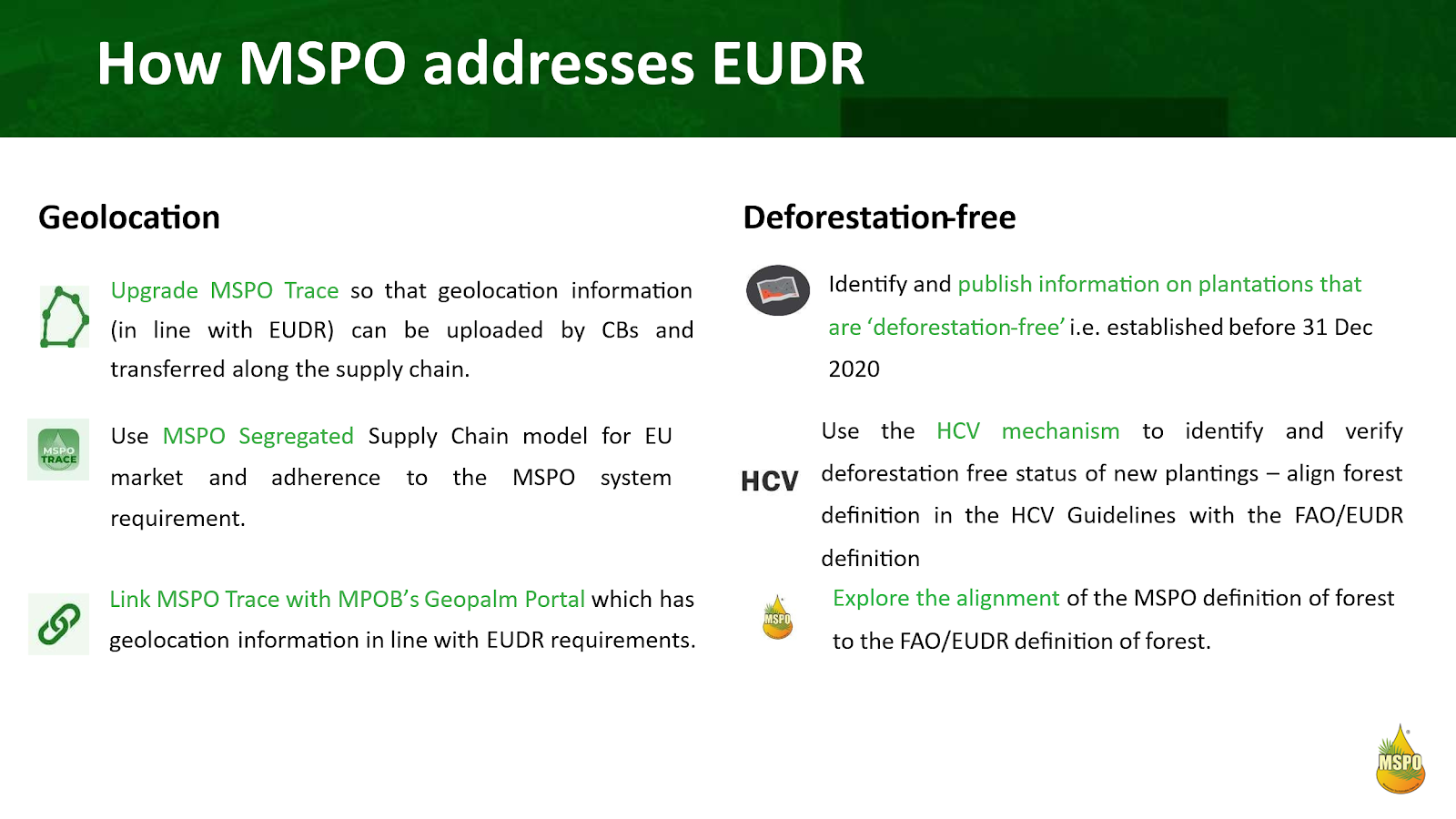

The MSPO is a national mandatory sustainability certification for palm oil operators. The newly enhanced MSPO 2.0 Standards include components such as High Conservation value (HCV), Greenhouse Gas (GHG) monitoring and control, Social Rights, Free Prior Informed Consent (FPIC), ILO Forced Labour Indicators and ILO Decent Work Agenda, Triangular Employment, Integrity, and Anti-Corruption to be in line with United Nations Sustainable Development Goals 2030 and addresses the EUDR requirements. MSPO has been listed in ITC standard map and acknowledged as one of the sourcing codes for sustainable palm oil procurement at the Tokyo 2020 Olympic and Paralympic Games, Expo Dubai 2020 and Expo Osaka 2025.

MSPO ACHIEVEMENT STATISTICS

As of 31 March 2025, a total of 84.65%, equivalent to 4.75 million hectares of oil palm planted areas in Malaysia, have been certified under the MSPO. Meanwhile, 86.45%, equivalent to 402 palm oil mills in Malaysia, have been certified under the MSPO.

UNIQUENESS/FUTURE PROJECTIONS

INTERNATIONAL MARKET OPPORTUNITIES

The international market potential for MSPO-certified products is growing, driven by increasing global demand for sustainably sourced palm oil. This is particularly evident in Japan and the East Asian region, where governments and industries are aligning with sustainability goals and ESG commitments targeting in 'greening' their supply chain and businesses. Notably, a total of 610075 tons of MSPO certified shipments to Japan were successfully exported under the sustainable sourcing code for palm oil in conjunction with the Tokyo 2020 Olympics and Paralympics Games 2021.

Besides, the endorsement of MSPO by the Green Gold Label (GGL) in Japan further strengthens its credibility, opening doors for wider acceptance and market access for MSPO certified biomass material. With rising awareness and preference for certified sustainable products, MSPO is well-positioned to meet the expectations of discerning international buyers.

PROPOSED NARRATIVE OR KEY MESSAGE

“Empowering a Sustainable Palm Oil Future”

At World Expo Osaka 2025, MSPO showcases Malaysia’s commitment to sustainable, responsible, and inclusive palm oil production. Through the MSPO certification, Malaysia is leading the way in ensuring that palm oil not only feeds the world but also nurtures communities, preserves biodiversity, and safeguards the planet for future generations.

Sustainability with Integrity

“MSPO represents a national commitment — from plantation to smallholder — to sustainability, transparency, and continuous improvement.”

- MSPO ensures environmental stewardship, zero deforestation, and conservation of biodiversity.

- Demonstrates traceability and responsible sourcing aligned with global standards.

Inclusive Growth

- “MSPO empowers over 250,000 smallholders to be part of the global sustainability movement.”

- Unique focus on inclusivity, ensuring no farmer is left behind.

- Capacity-building, fair pricing, and community upliftment are central to MSPO’s mission.

Globally Recognized, Nationally Driven

- “As a government-backed certification, MSPO reflects Malaysia’s national will to produce sustainable palm oil for the world.”

- Recognized regionally and gaining international credibility.

- Aligned with the UN SDGs and global ESG goals.

Innovation & Technology

- “From digital traceability to smart farming – MSPO supports innovation for better yields, lower emissions, and stronger compliance.”

- Embracing Industry 4.0 to support climate-smart agriculture.

- Investments in digital monitoring tools, audit transparency, and farm-level precision.

Partnerships for Global Impact

- “MSPO is your partner in sustainable supply chains – join us in transforming palm oil into a global force for good.”

- Open for collaboration with governments, buyers, NGOs, and technology providers.

- Promoting shared responsibility and benefit across the palm oil value chain.

INTRODUCTION

The Malaysian Rubber Council (MRC), under the Ministry of Plantation and Commodities, is the national agency mandated to promote high-quality Malaysian rubber and rubber products in global markets. Established in 2000, MRC advances the industry through strategic market promotion, commercialization support, and international collaboration, with overseas offices in the US, China, and India to strengthen global outreach, monitor regulatory shifts, and facilitate investment and R&D.

Malaysia is the world’s leading exporter of rubber gloves and a major producer of medical devices, industrial goods, and automotive components, with glove exports alone rising by 30.2% in 2024 and contributing to total rubber export earnings of RM23.7 billion. In 2024, Japan was Malaysia's third-largest export market for rubber products, accounting for 5% of the country's total rubber exports.

Malaysia's rubber product exports to Japan reached RM1,182.1 million, with rubber gloves being the primary export, comprising 79.4% of all rubber products shipped to the market. Through initiatives like the Fund for Automation and Green Technology (FAGT) and the Malaysian Rubber Industry ESG Conference (MREC), MRC champions quality, sustainability, and innovation while supporting industry players in meeting global standards and securing long-term trade opportunities.

This platform allows rubber industry stakeholders to gain insights into ESG regulations, share best practices, and explore sustainable growth opportunities. Looking ahead, MRC is driving diversification into eco-friendly, high-value products and nurturing a skilled workforce, ensuring a resilient and future-ready rubber industry aligned with national economic goals and international expectations.

CURRENT PROMOTIONAL INITIATIVES

A program entitled "Sustainable Living: Advancements in Made-in-Malaysia Rubber Products” will be staged at Malaysia Pavilion, Expo 2025 Osaka.

INTERNATIONAL MARKET OPPORTUNITIES, ESPECIALLY TO JAPAN AND THE EAST ASIAN REGION

Malaysia, renowned for its advanced manufacturing capabilities and expertise in rubber products, is strategically positioned to capitalize on the growing global demand for high damping rubber bearings (HDRBs), green precured treads, and biodegradable gloves. These rubber products made in Malaysia align with global trends towards sustainability, safety, and technological innovation.

High Damping Rubber Bearings (HDRBs)

High Damping Natural Rubber Bearings (HDNRB) made in Malaysia offer several key advantages, including effective seismic protection by isolating structures from vibrations, cost-effectiveness due to their simple design, and environmental sustainability through the use of sustainably sourced natural rubber. They are maintenance-free, proven effective in various high-profile projects worldwide, and versatile for different applications such as bridges and high-rise buildings. Additionally, the expertise of Malaysian manufacturers ensures the production of high-quality, reliable bearings that enhance safety and resilience in construction. HDRBs are crucial for enhancing the seismic resilience of buildings and infrastructure by absorbing and dissipating seismic energy, thereby reducing the impact of earthquakes. This is particularly important for regions with high seismic activity, where resilient infrastructure is essential.

Over 60% of natural rubber latex is used in producing precured tread, which is a biodegradable, a renewable and sustainable resources. Precured tread plays an important role of promoting sustainability, reducing environmental impact and lowering the carbon footprint of the tyre industry. Precured tread is applied in the retreaded tyre industry where used tyres are recycled and reused as if new tyre, thus eliminating/reducing waste tyres. The Malaysian precured treads manufacturer has developed green precured tyre tread liner, an innovative precured tread that is greener and perform better than the current product. The innovative tyre tread has recorded green material percentage of 70%. The new formulation also demonstrates positive results in tensile strength, modulus and wear resistance. The Green Precured Treads is expanding due to the increasing emphasis on sustainability and eco-friendly products.

To live in a smart and healthy environment, rubber gloves have become indispensable tools for personal protection in various settings, safeguarding individuals against chemical, biological, and physical hazards while promoting safety and hygiene. Malaysia is the world’s largest exporter of rubber gloves. A series of innovation and advancements have been made by the Malaysian glove manufacturers to improve performance, comfort and functionality. Ecofriendly materials are used in Malaysian glove manufacturing, such as natural rubber latex sourced from sustainable plantations and biodegradable synthetic materials. The demand for Biodegradable Gloves is expanding rapidly due to increasing environmental concerns and the push for sustainable products. Malaysia, being the world's largest exporter of rubber gloves, is well-positioned to meet this demand.

PROPOSED NARRATIVE OR KEY MESSAGE

A program entitled "Sustainable Living: Advancements in Made-in-Malaysia Rubber Products” will be showcased on the main stage. Get ready to experience an engaging journey through Malaysia’s innovative rubber industry. This dynamic showcase blends live choreography, music, and visuals to highlight eco-friendly advancements in rubber products, focusing on biodegradable gloves, green precured tyre treads, and high damping natural rubber bearings (HDNRB). From sustainable manufacturing to cutting-edge design, this programme brings to life the creativity and innovation behind Made-in-Malaysia rubber products and their role in promoting a smart, safe, and healthy future. All three featured rubber product innovations (biodegradable gloves, high damping natural rubber bearing (HDNRB), and green precured tread) will be displayed near the main stage and as well as the thematic corner. Interactive QR codes for each product will offer visitors instant access to indepth information about Malaysia's commitment to sustainability and innovation, including detailed insights into the featured rubber products and the Malaysian manufacturers and exporters.

INTRODUCTION

The timber industry is one of the key sectors contributing to the national economy, making it the third-largest export commodity after palm oil and rubber. Malaysia is renowned for its diverse range of tropical timber species and expertise in producing high-quality timber-based products.

In 2024, the Malaysian timber industry continued to demonstrate resilience and competitiveness, recording an export of RM22.92 billion—an increase of 4.9% compared to RM21.84 billion the

previous year. This growth was mainly driven by the increase in exports of wooden furniture as well as builder’s joinery and carpentry products.

With the rising global demand for sustainable materials, Malaysia’s timber industry holds strong potential for continued growth through product innovation, compliance with environmental standards, and

exploration of new markets.

CURRENT PROMOTIONAL INITIATIVES

The timber sector will be organising two sessions of Pocket Talk entitled “What You Need To Know About Sustainable Timber From Malaysia”.

The first session will be held on Thursday from 2.00 pm to 4.00 pm while a repeat session will be held on Friday from 11.00 am to 1.00 pm.

This programme is organised by the Malaysian Timber Council (MTC) in collaboration with the Malaysian Timber Industry Board (MTIB) and Malaysian Timber Certification Council (MTCC). Besides that, MTIB will also be organising a wood carving demonstration to promote the art of wood carving as a means of raising awareness about Malay heritage arts and culture, particularly in Malaysia.

INTERNATIONAL MARKET OPPORTUNITIES, ESPECIALLY TO JAPAN AND THE EAST ASIAN REGION

Japan and the East Asian region are important export markets for Malaysia.

Japan is Malaysia's third-largest export destination for timber products.

In 2024, Malaysia exported RM2.85 billion worth of timber products to Japan, recording a 1% increase compared to RM2.83 billion in the previous year.

This growth was primarily driven by increased exports of plywood and wooden furniture. The market opportunities for Malaysian timber products in Japan are vast and highly promising, especially in meeting the

demand for high-quality, sustainable, and certified products

PROPOSED NARRATIVE OR KEY MESSAGE

About MTC

- Connecting and strengthening Malaysia’s timber industry with global trade partners

- Enhancing the industry’s position by showcasing the capabilities of the timber sector

- Promoting the industry’s contribution to the national economy and highlighting Malaysia’s Sustainable

- Forest Management (SFM) practices

- Advocating the benefits of wood as a sustainable and eco-friendly material

- Promoting the Malaysian Wood Expo (MWE) 2025

You are invited to join the Pocket Talk session themed “What You Need To Know About Sustainable Timber From Malaysia” to gain deeper insights into Malaysia’s sustainably sourced timber products.

PELANCARAN MINGGU KOMODITI DI EKSPO 2025 OSAKA

9 JUN 2025 | OSAKA, JAPAN

Kementerian Perladangan dan Komoditi Malaysia (KPK) telah melancarkan Minggu Komoditi Malaysia di Ekspo 2025 Osaka, Kansai yang berlangsung dari 9 hingga 15 Jun 2025. Minggu khas ini mengetengahkan kepimpinan Malaysia dalam sektor komoditi seperti sawit, getah, kayu-kayan, koko, lada dan kenaf.

Majlis pelancaran rasmi di Pavilion Malaysia telah disempurnakan oleh Timbalan Ketua Setiausaha (Perancangan Strategik dan Pengurusan) KPK, YBhg. Dato’ Abdul Hadi Omar. Dalam ucapannya, beliau menekankan komitmen Malaysia terhadap kelestarian, teknologi canggih serta inovasi dan penyelidikan berterusan dalam sektor ini.

Selaras dengan tema Ekspo “Designing Future Society For Our Lives”, Minggu Komoditi Malaysia memberi peluang kepada pengunjung untuk memahami visi Malaysia dalam membangunkan agrikomoditi secara mampan dan inovatif, demi menyokong kehidupan masa depan yang harmoni di peringkat global.

Sebagai tambahan menarik, watak animasi popular “Upin dan Ipin” turut memeriahkan acara pelancaran. Pelbagai aktiviti dianjurkan sepanjang minggu ini bagi menggalakkan kolaborasi antarabangsa dalam sektor agrikomoditi.

#MalaysiaMADANI

#MyKomoditi

#KPK

#WorldExpo2025Osaka

Foto kredit: Kementerian Pelaburan, Perdagangan dan Industri (MITI)

------------------------------------------------------------------------------------------

MAJLIS MENANDATANGANI MEMORANDUM PERSEFAHAMAN (MoU)

????? ???? ?????, ?????? ??????? ???

9 JUN 2025 | OSAKA, JAPAN

Kementerian Perladangan dan Komoditi (KPK) telah menandatangani lima perjanjian penting dengan syarikat terkemuka Jepun sempena pelancaran rasmi Minggu Komoditi Malaysia di Ekspo 2025 Osaka. Perjanjian ini bertujuan untuk mengukuhkan kerjasama serta pembangunan mampan dalam sektor komoditi utama negara.

Majlis menandatangani Memorandum Persefahaman (MoU) ini telah disaksikan oleh Timbalan Ketua Setiausaha (Perancangan Strategik dan Pengurusan) Kementerian Perladangan dan Komoditi (KPK), Dato’ Abdul Hadi Omar. Sebanyak lima MoU telah dimeterai, yang melibatkan kerjasama strategik antara Malaysia dan Jepun dalam pelbagai sektor komoditi seperti berikut:

1. Malaysian Sustainable Palm Oil (MSPO) dan Global Alliance for Sustainable Supply Chain (ASSC) akan bekerjasama dalam mempromosikan pensijilan MSPO di Jepun bagi memperluas pengiktirafan minyak sawit mampan Malaysia di pasaran antarabangsa;

2. Lembaga Minyak Sawit Malaysia (MPOB) dan Panasonic Housing Solutions Co. Ltd. akan menjalankan penyelidikan bersama mengenai penggunaan sisa sawit dalam pembangunan bahan binaan mampan;

3. MPOB turut bekerjasama dengan Asano Gear Factory Co. Ltd. bagi membangunkan teknologi serta peralatan penuaian sawit yang lebih cekap dan berinovasi tinggi;

4. Saraspice Sdn Bhd dan Vox Trading Co. Ltd. akan menjalinkan kerjasama dalam memasarkan lada hitam mampan dari Sarawak ke pasaran Jepun; dan

5. Green Advantex Sdn Bhd dan SIIX Co. Ltd. akan meneroka penggunaan kenaf sebagai bahan termaju dalam pelbagai industri berteknologi tinggi seperti aeroangkasa, automotif, dan robotik.

Kerjasama strategik ini mencerminkan komitmen Malaysia terhadap inovasi, kelestarian dan perluasan pasaran komoditi di peringkat global. Minggu Komoditi Malaysia diteruskan dengan sesi perniagaan, jaringan kerjasama dan pameran produk bagi mengukuhkan hubungan ekonomi Malaysia–Jepun.

#MalaysiaMADANI

#MyKomoditi

#KPK

#WorldExpo2025Osaka

Foto kredit: Kementerian Pelaburan, Perdagangan dan Industri (MITI)